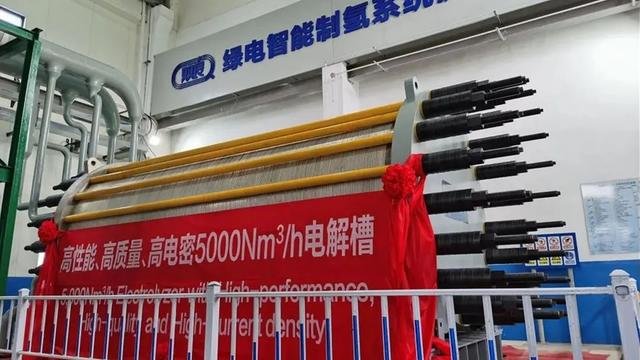

In a groundbreaking development for the clean energy sector, Shuangliang Group, a prominent Chinese firm, has introduced the world’s largest alkaline water electrolyzer.

The unveiling took place at the company’s inaugural innovation conference on October 18, marking a significant milestone in large-scale hydrogen production.

This new technological marvel is engineered to produce approximately 990 pounds of hydrogen per hour, showcasing extraordinary efficiency.

With an operational capacity of 5,000 normal cubic meters per hour (Nm³/h), the device sets a new standard in hydrogen generation by utilizing less than 43.09 kWh of electricity per kilogram of hydrogen produced.

This efficiency positions the electrolyzer as a leader in its field, overshadowing other devices worldwide.

Alkaline electrolysis is a process that involves an electrolyte, typically a concentrated solution of potassium or sodium hydroxide, which functions with a porous inorganic diaphragm and specialized electrodes.

When an electrical current passes through, it splits water into oxygen and hydrogen, facilitating the production of hydrogen gas ready for storage and utilization.

The new electrolyzer’s design is especially advantageous for industrial applications necessitating large hydrogen volumes, such as steel production, chemical manufacturing, and hydrogen fuel creation.

The production process is powered entirely by renewable energy, ensuring that it generates no carbon dioxide emissions, a crucial aspect of the initiative towards a cleaner, sustainable energy future.

Hydrogen itself is integral to various growing sectors, including fuel cell technology for transportation and energy generation.

It also serves as an essential raw material in creating ammonia, vital for the chemical industry.

The innovation conference, which spotlighted this electrolyzer, was attended by over 200 experts, scholars, and industry leaders.

The event focused on emerging trends in clean energy and laid foundations for strengthening industrial innovation.

Shuangliang not only introduced the electrolyzer but also formed the Photovoltaic Hydrogen Storage Ammonia Alcohol Integration and Application Innovation Consortium.

Furthermore, they launched the Key Laboratory of Clean Energy Technology and Equipment and signed a strategic cooperation agreement with Grove Hydrogen Energy Technology Group Co., Limited.

While the electrolyzer spearheads efficiency within its category, it is only surpassed by solid-oxide machines, which operate with external heat sources.

Other emerging technologies include capillary-fed electrolyzers and AEM machines developed by Cipher Neutron, illustrating the potential for further advancements in the field.

In conclusion, the new electrolyzer from Shuangliang Group represents a progressive leap in hydrogen production technology, promising to reshape industrial applications and promote sustainability initiatives globally.

As industries continue to pivot towards cleaner energy solutions, innovations like these mark significant progress towards a greener future.