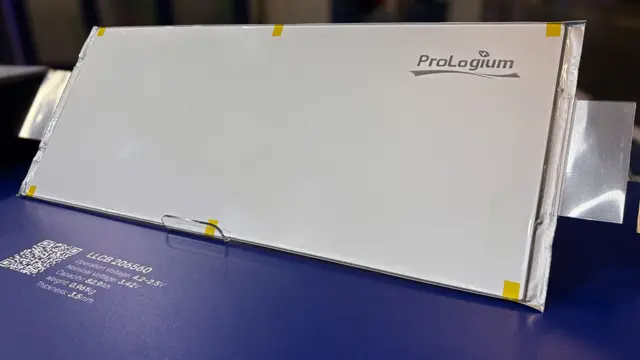

ProLogium Technology has made a significant splash in the electric vehicle (EV) market with its groundbreaking release of the world’s first 100% silicon composite anode battery.

Debuting at the 2024 Paris Motor Show, this innovative advancement marks a turning point in EV technology and is poised to reshape the industry’s landscape.

The 100% silicon composite anode battery by ProLogium promises remarkable performance by greatly enhancing energy density and charging efficiency.

The partnership with Germany’s FEV Group has been instrumental in developing this next-generation battery pack.

Certified by TÜV Rheinland, a globally recognized testing organization, this battery has set new standards for energy density and fast-charging capabilities.

ProLogium’s new battery technology boasts an impressive volumetric energy density of 749 Wh/L and a gravimetric energy density of 321 Wh/kg.

Projections indicate these figures could rise to 823 Wh/L and 355 Wh/kg by the year’s end.

Such specifications are a significant leap from traditional lithium-ion batteries, including lithium iron phosphate (LFP) and lithium-nickel-manganese-cobalt (NCM) batteries, which typically range under 200 Wh/kg to 300 Wh/kg.

The battery’s fast-charging capabilities are another standout feature, enabling users to charge from 5% to 80% in only 8.5 minutes.

This is a drastic reduction in charging time compared to the industry average of 30 minutes, reducing wait times by approximately 83.3% and increasing vehicle range to around 300 kilometers from just a five-minute charge.

Further enhancing its appeal, ProLogium has introduced the “Small Battery, Big Future” concept, emphasizing efficiency, performance, and sustainability.

With only 66% of the energy capacity compared to current lithium-ion counterparts, the battery reduces vehicle weight by 300 kg, thus benefiting both energy efficiency and driving range.

Additionally, the modular design of the battery facilitates easier repairs and enhances recyclability, effectively lowering maintenance costs while boosting the residual values of used EVs.

This innovative architecture directly helps reduce the total cost of ownership, offering a more accessible and sustainable EV solution for consumers.

The strategic partnership with FEV Group was also highlighted at the Paris Motor Show, underlining ProLogium’s progress from producing components to developing complete battery modules and packs.

This collaboration underscores a substantial stride forward in the commercialization of lithium ceramic batteries.

Vincent Yang, ProLogium’s Founder and Chairman, emphasized the company’s ambition to be a transformational force in the market, breaking through existing barriers while addressing prevalent challenges in the EV industry.

The Chief Scientist, Dr. Dmitry Belov, mentioned that their technology continues to widen the performance gap with competitors, particularly in energy density and fast-charging efficiency.

ProLogium’s debut at the Paris Motor Show represents a decisive step towards the widespread adoption of its LCB technology within the electric vehicle industry, promising a future where charging stations are less of a bottleneck, and the shift towards electric mobility gains further momentum.