An inventive breakthrough in sustainable technology comes from waste polystyrene, commonly seen in packaging materials.

Researchers from RMIT University, in collaboration with Riga Technical University in Latvia, have engineered a device that generates static electricity using wind and movement.

This innovation offers a promising solution to reduce power consumption by recycling energy waste, especially in air conditioning systems.

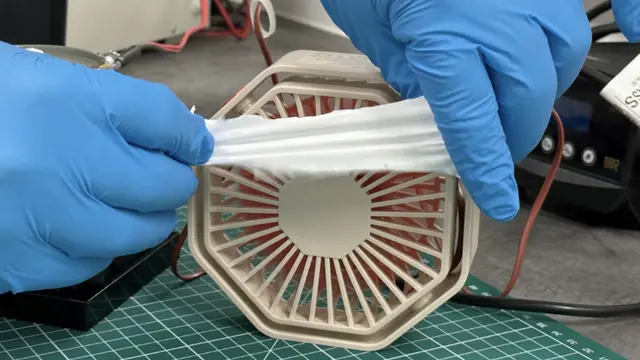

The new technology involves creating ultra-thin patches formed from multiple layers of polystyrene, each layer being about a tenth the thickness of a human hair.

These layers produce static electricity when airflow causes them to move, presenting a novel means to harness energy.

“We can generate electricity simply by air passing over these patches and then capture this energy,” explains Dr. Peter Sherrell of RMIT University, who led the research team.

In recent experiments, the patches have generated voltages up to 230 volts, comparable to household mains voltage, albeit at a lower power.

The researchers point out that the device’s efficiency improves with more substantial, faster movements.

This property makes it particularly suited for collecting energy from the chaotic airflows of AC units, potentially reducing energy demands by up to five percent and lowering their overall carbon footprint.

Beyond air conditioners, Dr. Sherrell suggests that these patches could be strategically installed in areas with high foot traffic, such as underground pathways, to supplement local energy supplies without adding pressure to the power grid.

The key to this technology is the upcycling of expanded or foamed polystyrene waste into electromechanically responsive triboelectric laminates (TLs), which contain internal dipoles that offer an eco-friendly alternative to traditional ferroelectric materials.

This method involves electrospinning layers of polystyrene fibers with varying diameters to establish a dipole moment when the layers experience friction.

Remarkably, the PS-TENG (Polystyrene Triboelectric Nanogenerator) device maintains strong stability, capable of charging a small capacitor effectively during testing, showcasing durability comparable to advanced piezoelectric materials.

The device’s application for generating electricity is backed by research published in Advanced Energy and Sustainability Research.

Given the long degradation period of polystyrene in landfills, this makes the patches a sustainable energy solution, likely to function effectively for extended periods. Sherrell also highlights the potential to enhance energy generation by adding more polystyrene layers.

The research team continues to explore other types of single-use plastics for making similar energy-generating patches, looking for variations in energy output based on plastic composition and structure.

RMIT has filed a provisional patent to secure intellectual property for this invention while seeking industrial partnerships to propel its development toward commercial applications.

Ultimately, the deployment of this technology could provide a new dimension in reducing waste and promoting sustainability in everyday energy usage.