A team of scientists from Woods Hole Oceanographic Institution (WHOI) has made a groundbreaking discovery in the fight against ocean plastic pollution.

They have identified cellulose diacetate (CDA), a bioplastic made primarily from cellulose found in plant walls such as cotton and wood pulp, as the fastest-degrading plastic in marine environments.

CDA has been in use for over a century, appearing in everyday items like sunglasses and cigarette filters.

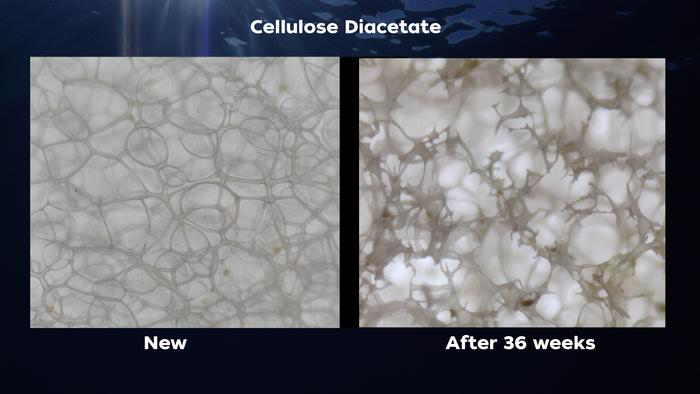

Researchers have now found a way to “foam” this material, rendering it porous and dramatically enhancing its degradation rate in the ocean—up to 15 times faster than its solid form and even surpassing paper, which is renowned for its environmental friendliness.

In a controlled lab experiment at WHOI, foamed CDA underwent a rigorous 36-week testing period in seawater flowing from Martha’s Vineyard Sound.

Under simulated natural marine conditions, researchers observed an impressive 65-70% reduction in the mass of CDA foam.

The significance of this finding is emphasized by the study’s senior author, Collin Ward.

He pointed out, “We translated the foundational knowledge into the design of a material that meets consumer needs and break downs faster in oceanic environments than any known plastic, even paper.”

This is a significant stride towards addressing the ubiquitous issue of plastic pollution with viable, ecologically friendly solutions.

Notably, traditional plastics such as Styrofoam showed no measurable degradation under the same conditions, highlighting CDA’s potential in drastically cutting down the persistence of plastic waste in the ocean.

The foamed version of CDA opens doors for commercial applications, with collaborations already underway.

Eastman, a bioplastic manufacturer, has partnered with WHOI scientists to explore the practical uses of this innovation.

A notable result of this partnership is the release of an eco-friendly tray designed to replace the industrious but environmentally damaging Styrofoam meat trays.

Foamed CDA’s promising performance in ocean conditions extends beyond this one application.

With further development, it could become a standard for products seeking to minimize their environmental footprint, pushing industries towards more sustainable practices.

Given the alarming rate at which plastic enters our oceans, transitioning industries towards materials like CDA could significantly mitigate pollution levels.

This shift could direct future policies towards prioritizing the usage of biodegradable materials in everyday items.

The implications of these findings are immense.

As confirmed by the study published in ACS Sustainable Chemistry & Engineering, the use of biodegradable materials aligns with global efforts to curtail plastic pollution and preserve marine life for future generations.

In conclusion, the discovery of foamed CDA presents a viable path to tackle one of the planet’s most pressing environmental challenges.

With continued research and adoption of these innovative materials, a future free from the detrimental impacts of plastic pollution could be within reach, bringing hope to preserving our oceans.